Conversion of flatbed full transport longarm 75cm from one-needle to double-needle

Conversion of flatbed full transport longarm 75cm from one-needle to double-needle :

Completed tasks:

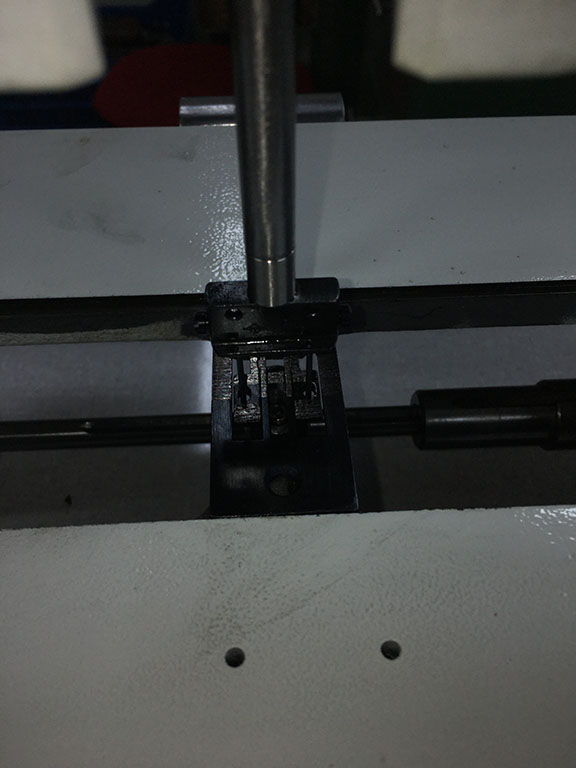

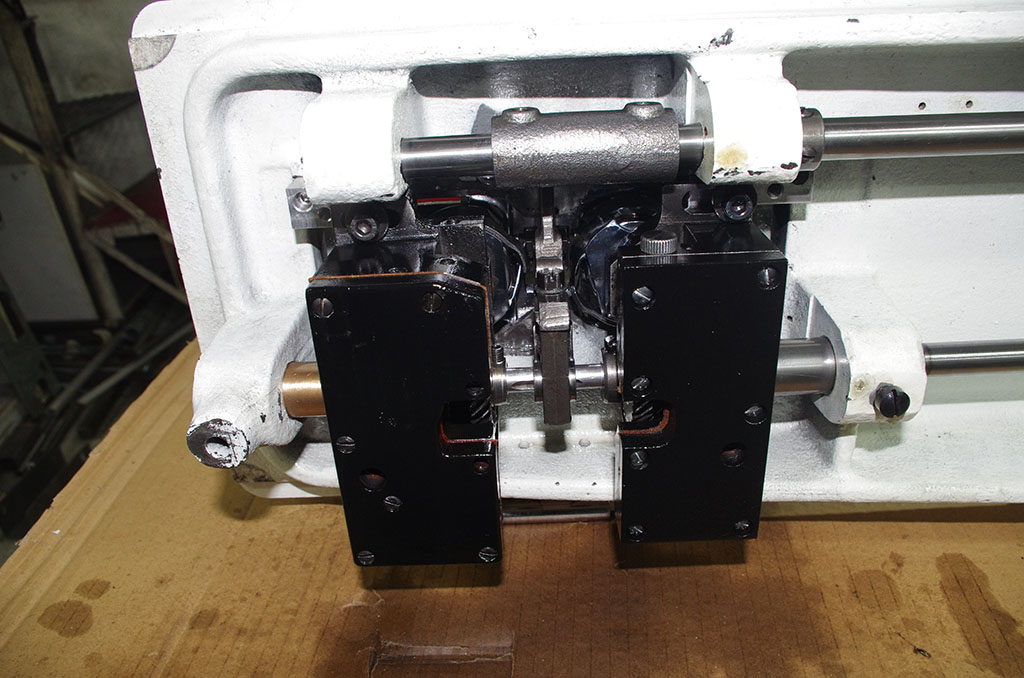

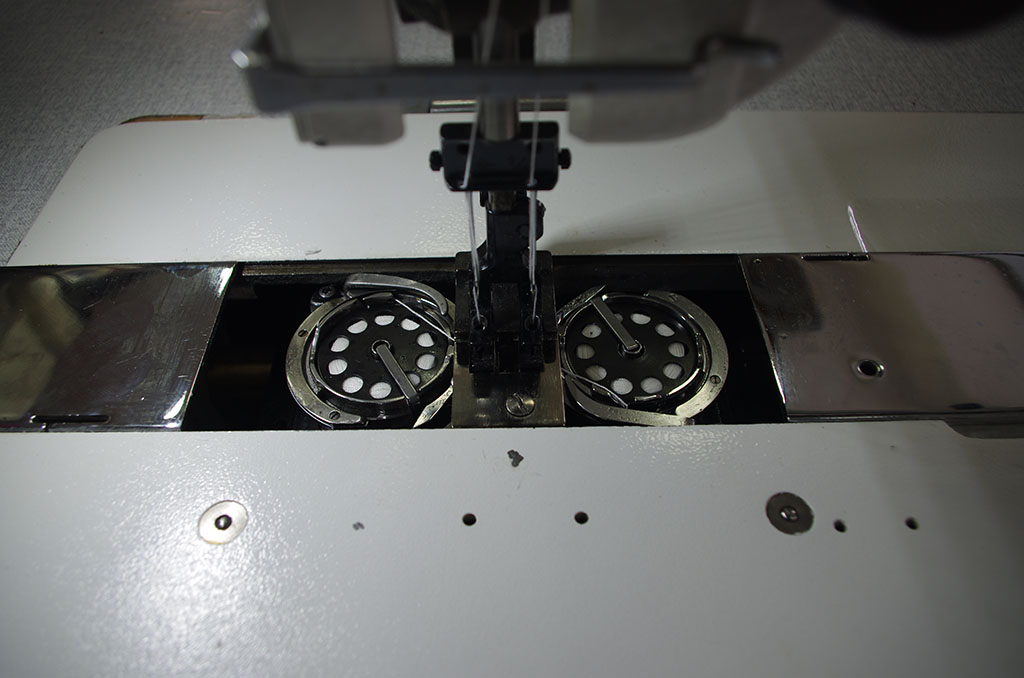

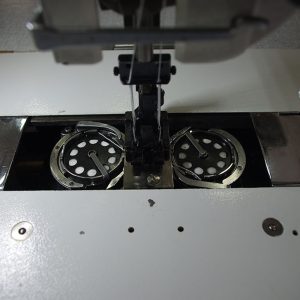

- Conversion of a different group hook that matches the rest.

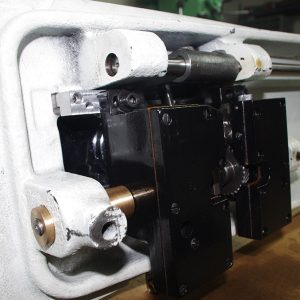

- Construction of a phosphorous bronze bearing supporter.

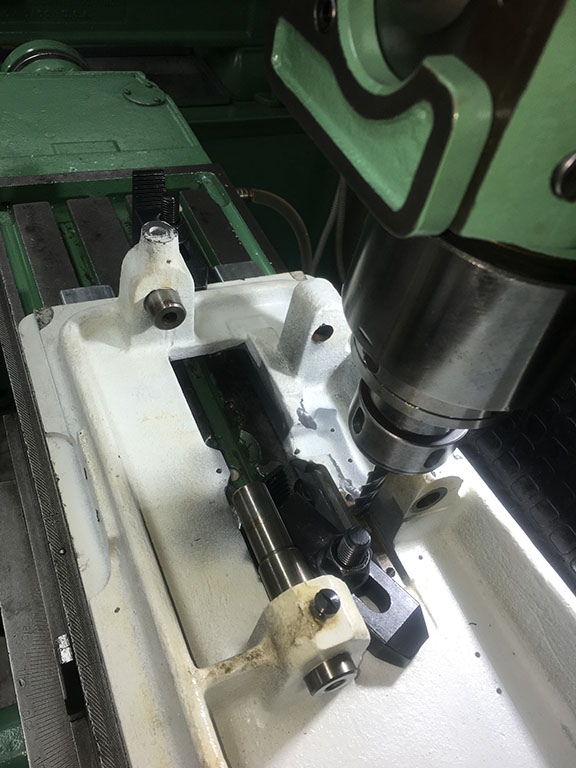

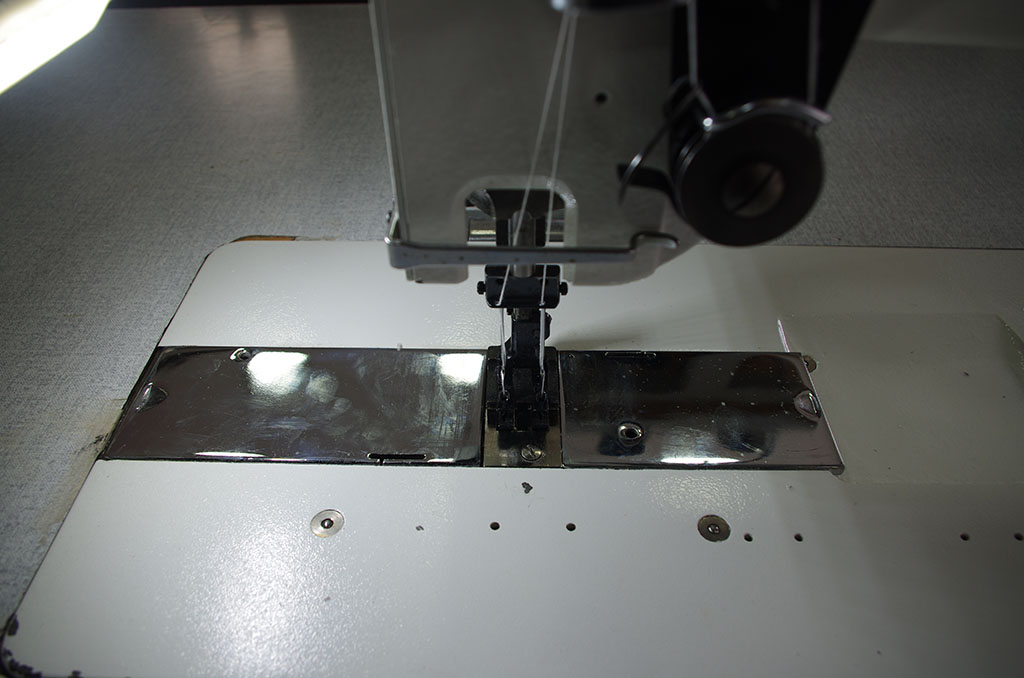

- Conversion and placement of set, feet, needle plate, needle bar and tooth to 14mm (9/16”). As you can see, it is possible to make it happen, despite there are no such gauge of needles.

- Conversion of thread tension plate so that it can support a second thread tension, and both can open when the machine operator pulls up the foot and takes out the working piece.

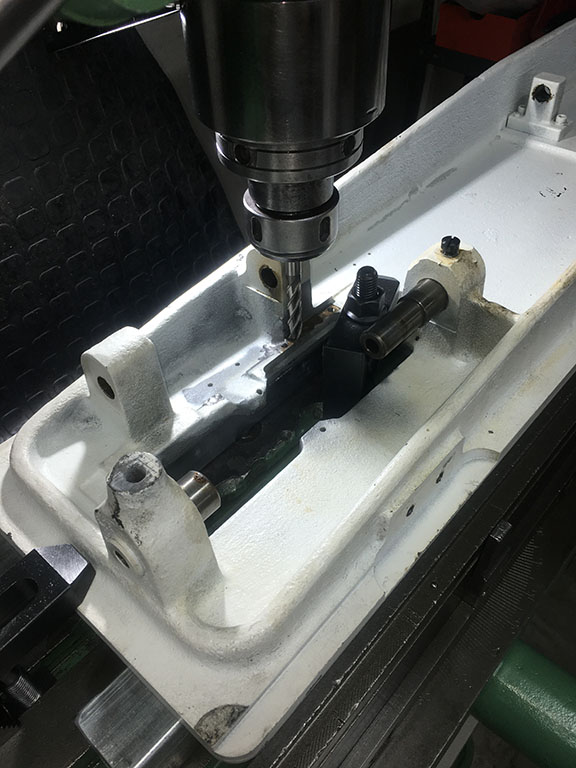

- The machine divided in the middle (then restrained in manual milling machine), so two new adaptors could be constructed to support the two groups.

- Construction of two same supporting bases (hook shaft saddle holder) for the two hooks

- Attachment of a dc brushless motor with pulse generator for needle position and a led lamb.

The working tasks were completed in our workshop in manual milling machine and manual lathe.